Modeling Complex Systems

by Taras Alexander Mykytyn

The INCOSE Systems Engineering Vision - 2025 paper sets the foundation for rest of the year for the monthly President’s Point of View (POV) articles. February’s POV article covered the topic of Fostering Mentorship for STEM Students. This is extremely important in enhancing the education of the future systems engineering profession and enticing students to become more comfortable and active in STEM-related education and activities.

This month’s article will focus on Modeling Complex Systems, and why the SE and STEM community needs to step up their skills and expertise in understanding the driving requirements for complex systems, system and subsystem inter-dependencies, system-of-systems complexity, and future challenges for all industries. As the expansion of products and services go beyond local and country boundaries, to a more global solution space, SEs and STEM professionals need to think on a more broad and global scale to address these challenges.

The challenges in society and the world for engineering and STEM disciplines goes beyond just having expertise within their specific discipline. It now requires that teams coordinate and collaborate across multi-disciplines, to bring together solutions that address diverse technical skills covered now at a more global scale. These systems must not only meet performance and functionality required, but they must also cover the details of how they are interconnected, their interdependencies across a global scale, and level of complexity in the full life-cycle of the system. Noted below are the eight system characteristics that are expected to be addressed as the stakeholder drivers:

Sustainability – “acceptable total cost of ownership; full product life cycle management; management of product diversity; pre-planned product evolution; upgrades while operational; and conservation of natural resources”.

Scalable – “systems are adaptable to a range of performance and system capabilities without breaking their fundamental architecture”, to eliminate recurring investment of the initial high costs of the infrastructure.

Safe – “system safety is a major concern due the nature of more software-intensive designs”.

Smart – “systems are able to cope with a changing and unknown environment, assist human operators, or self-organize to provide unanticipated products and services”.

Stable – “systems of the future must be stable and reliable in order to meet key operational requirements and availability needs; achieve customer acceptance; operate efficiently; avoid liability; and provide expected system value”.

Simple – “systems are maintainabile and avoid operator error, with fault tolerance built in”.

Secure – “system complexity, global connectivity, and IT-dependence give rise to system vulnerability, requring cyber security and cyber defense against unwanted intrusions, cyber threats, and unwanted take-over of system capabilities.”

Socially Acceptable – “systems need to address social, environmental, and economic concerns of sustainability”.

Modeling, simulation, and visualization can pull together various teams with expertise in specific areas and also with diverse backgrounds of design, engineering, hardware and software expertise, production, and operations and support disciplines. Collaborating across multiple engineering disciplines, across component and subsystem teams, and with hierarchical design standards and requirements, can ensure successful engineering, development, and production of very complex systems.

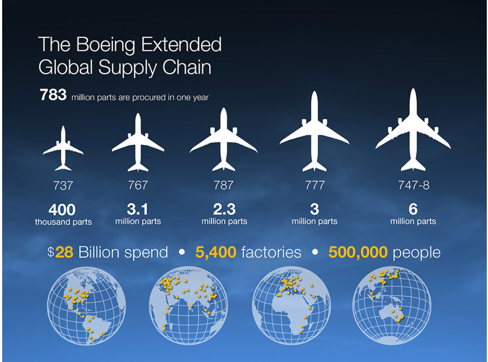

A prime example of this is the Boeing 787 Dreamliner effort. The industry-leading technology of the 787 Dreamliner entailed unparalleled fuel efficiency for greater flying ranges and allowed for new routes to optimize a carrier’s fleet; global partnerships were required with extensive coordination, engineering, automation, and production processes using new technology and tools; and employed a tremendous improvement in comfort and user experience for the customer to bring about “a better way to fly.”

The Boeing 787 Dreamliner expanded on the partnering and collaboration across many suppliers and producers of the various components/subsystems for this next generation fleet of airplanes. The INCOSE SE Vision – 2025 paper stated that: “visualization and simulation helped identify incompatibilities in interfaces and assembly processes early in the design before hardware costs were fully committed, avoiding costly redesign late in the system design life cycle”.

The future links noted below provide insight into the history, challenges, engineering, production, and supply chain documenting the successes for this new airplane from Boeing.

Boeing 787 Dreamliner History – timeline of the history of the Boeing 787.

Smithsonian Air and Space Magazine article presenting insight into the challenges Boeing had for assembling the planes – Inside Boeing’s 787 Factory.

Interesting article on the level of collaboration that occurred for the design phase of the 787 Dreamliner – For Boeing, It Takes a Village to Build a New Airplane.

A case study reviewing technology used to address the complexity of the Boeing 787 –Technology and Operations Management - A Course at Harvard Business School: Boeing: Using Digital to Address Complexity: “Boeing is using a diverse digital toolkit – tools such as augmented reality, cloud computing, internet of things (IoT), and advanced analytics – to meet both its own and its customers’ operational challenges”. Supply chain management is just one of the many complex challenges that Boeing needs to address for all of their suppliers.

Video, titled Building the 787-9 Dreamliner, presenting a time lapse video of the transportation, integration, and build of this magnificent aircraft.

Article on the increased ingenuity of the engineering teams to make the 787 a global partnership success in developing, designing, and producing this airliner.

Boeing Web site presenting the complexity of the Dreamliner and how engineers across the globe have achieved a remarkable set of milestones and capabilities to produce the 787.

Case analysis for the Boeing 787, where the complexity of the life cycle for the 787 Dreamliner is captured.

Wikipedia write-up on the scale of the various manufacturers and suppliers to make the 787 a successful global engineering and production program.

The technology and tools available today are just the starting point of what may be achievable in the future. Simulation and visualization play a key role in understanding the complexity of systems before committing to costly investments to verify solutions before building them. Model-based Systems Engineering (MBSE) provides integrated modeling environments that can mimic the behavioral and physical attributes of systems prior to building any major component or subsystem. Virtual reality and modeling enable replication of concepts and designs into pre-production of components prior to building the final versions. 3D printers are advancing to the point that they not only can generate the prototypes, but actually produce the final components for operations. Advanced analytic techniques can surface key inter-dependencies and performance issues before costly re-engineering or production occurs. Cloud-based computing can enhance the modeling and simulation and data analysis capabilities shared across the program stakeholders. Collaboration tools support automated workflow, direct interaction between globally dispersed engineering experts, and increasing the agility of software and engineering development. Decision support tools augment modeling and simulation with data-driven information to make informed decisions on technical and programmatic decisions. Systems engineering can focus on ensuring that the all the pieces in a complex program work together to achieve the objectives of the program, while balancing the requirements against other factors.

SEs and STEM-related professionals can take the lessons learned from the Boeing 787 Dreamliner program and identify and scale the successes from this global engineering partnership to apply to their specific project or program. Systems are becoming more and more complex. There are greater inter-dependencies among project teams, solutioning partners, and suppliers. Capabilities delivered are addressing global scalability, but yet focused on local and regional needs for the customers. Expectations are that engineering solutions and products must address social, environmental, and economic issues, as well as the coordinated efforts of the technical design, development, integration, testing, and support teams. Understanding these relationships and working with all technical and programmatic teams, SEs can ensure that future products and services will cover the eight major system characteristics that stakeholders are driving toward. We only have one planet, but we have many opportunities to correctly address the technical challenges through better engineering for global solutions. INCOSE can work with professionals in the SE and STEM-related areas to prepare them for the future. Doing engineering correctly is critical to the future of our planet and delivering capabilities that address the concerns and global sustainment in an economical and environmentally friendly manner to better society as a whole.

The next POV articles will start to address the human and societal needs noted in the INCOSE SE Vision – 2025 article. Stay tuned and stay engaged with the POV articles. Your feedback and comments are greatly appreciated.